Bearings, Seals, and Gaskets: These components play a pivotal role in industrial machinery and conveying equipment. To ensure longevity and reliability, we recommend polymers with exceptional abrasion resistance. Our portfolio includes:

Thermoplastic Polyurethanes (TPU): Versatile and wear-resistant, TPUs excel in applications where durability is essential.

Nylons (PA6 and PA6,6): Known for their strength and toughness, nylons withstand harsh conditions and provide excellent abrasion performance.

Acetal (POM): Acetal combines low friction with high stiffness, making it an excellent choice for precision components.

Additives: We enhance our materials with additives like Silicon or PTFE to further boost wear resistance.

Chemical Resistance: Given the nature of industrial applications, chemical resistance is crucial. Our polymers are designed to withstand aggressive substances, ensuring reliable protection.

Flame Retardant Solutions: Depending on the part’s location, flame retardancy may be essential. Our portfolio includes flame-resistant materials that meet safety standards without compromising performance.

At Resinex, we prioritise quality. Explore our broad range of solutions and elevate your industrial processes.

Related Products

Market Segments

Agriculture & garden

One of the advantages of using plastic in agriculture and gardening applications is its ability to withstand corrosion in the outdoor environment, as well as the range of colours that can be produced.

Predominantly garden furniture can be made from PP (Polypropylene) and garden pots and planters in varying colours can brighten the garden further.

Ultraviolet stability (UV) is essential to stop colours from fading and maintain properties for as long as possible.

Applications may require a level of impact and toughness to withstand the environmental pressures of the outdoors, wtih temperature fluctuations and the use of chemicals.

Within agriculture, applications range from rotomoulded containers using Polyethylene, carrying fertilisers and feedstuffs, used for their durability and lightweight properties down to piping for irrigation systems. Common types of materials used are:

PE

PVC

PP

Polycarbonate (PC) is often used in greenhouses due to its clarity and impact resistance.

Applications

Agriculture & garden

One of the advantages of using plastic in agriculture and gardening applications is its ability to withstand corrosion in the outdoor environment, as well as the range of colours that can be produced.

Predominantly garden furniture can be made from PP (Polypropylene) and garden pots and planters in varying colours can brighten the garden further.

Ultraviolet stability (UV) is essential to stop colours from fading and maintain properties for as long as possible.

Applications may require a level of impact and toughness to withstand the environmental pressures of the outdoors, wtih temperature fluctuations and the use of chemicals.

Within agriculture, applications range from rotomoulded containers using Polyethylene, carrying fertilisers and feedstuffs, used for their durability and lightweight properties down to piping for irrigation systems. Common types of materials used are:

PE

PVC

PP

Polycarbonate (PC) is often used in greenhouses due to its clarity and impact resistance.

Applications

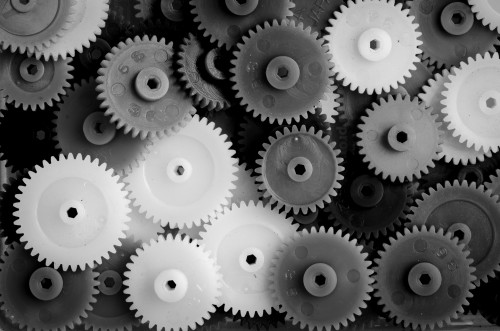

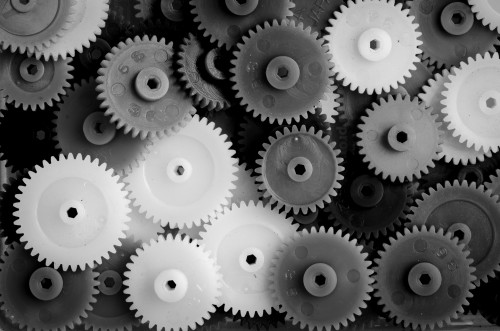

Conveying systems

The different parts of a conveyer system involve:

a belt and rollers - to move product from one place to another

driven by a motor - this can be using hydraulics or pneumatics

may need food approval

may need to be chemically resistant

With this in mind there are a range of materials that can be used in these applications.

PVC - due to its flexibility and strength,

Acetal (POM) - in its natural form or with addtives such as Silicon and PTFE (fluoroplymer)

Nylons (PA6 or PA6,6) for its durability, impact resistance and wear

Applications

- Conveyer belt

- Gears

- Tensioners / adjustable pulley

Conveying systems

The different parts of a conveyer system involve:

a belt and rollers - to move product from one place to another

driven by a motor - this can be using hydraulics or pneumatics

may need food approval

may need to be chemically resistant

With this in mind there are a range of materials that can be used in these applications.

PVC - due to its flexibility and strength,

Acetal (POM) - in its natural form or with addtives such as Silicon and PTFE (fluoroplymer)

Nylons (PA6 or PA6,6) for its durability, impact resistance and wear

Applications

- Conveyer belt

- Gears

- Tensioners / adjustable pulley

Fluid handling / Hydraulics

The handling of fluids and gases often involves an intricate system of pumps, containers and control systems and is used in many industries such as food, beverage and chemical manufacturing.

Within the process there are several applications using plastic.

PVDF (Polyvinylidine Fluoride) is used for its chemical resistance and durability.

PP and PE are used in piping and pumps as well as filters for their dimensional stability and ease of processing.

PVC is also used for piping and can be used to make valves to control the flow.

ABS is also an option for pumps.

PE can be rotomoulded to make hollow, rigid storage tanks that offer a level of chemical resistnce.

The control of heat via a heat exchanger can be achieved using PP, PE or PVDF

Resinex can offer a range of engineering and commodity materials depending on the application.

Applications

- Pumps

- Valves

- Piping and tubing

- Filters

- Storage tanks

- Heat exchangers

Fluid handling / Hydraulics

The handling of fluids and gases often involves an intricate system of pumps, containers and control systems and is used in many industries such as food, beverage and chemical manufacturing.

Within the process there are several applications using plastic.

PVDF (Polyvinylidine Fluoride) is used for its chemical resistance and durability.

PP and PE are used in piping and pumps as well as filters for their dimensional stability and ease of processing.

PVC is also used for piping and can be used to make valves to control the flow.

ABS is also an option for pumps.

PE can be rotomoulded to make hollow, rigid storage tanks that offer a level of chemical resistnce.

The control of heat via a heat exchanger can be achieved using PP, PE or PVDF

Resinex can offer a range of engineering and commodity materials depending on the application.

Applications

- Pumps

- Valves

- Piping and tubing

- Filters

- Storage tanks

- Heat exchangers

General

Where conditions are much more extreme, it is essential that some of the plastic parts manufactured in our every day lives, but used in the industrial sector, have much more stringent requirements.

PPS (Polyphenyline Sulphide) and PA4,6 offer chemical and heat resistance for the more extreme environment as well as a corrosion resistance and dimensional stability without swelling. Noise and vibration damping are often a factor to reduce effects in the work place.

Applications

- Industrial machinary parts

- Fittings and fixtures

- Impellor for a water pump

- Flexible packaging

- Filters

General

Where conditions are much more extreme, it is essential that some of the plastic parts manufactured in our every day lives, but used in the industrial sector, have much more stringent requirements.

PPS (Polyphenyline Sulphide) and PA4,6 offer chemical and heat resistance for the more extreme environment as well as a corrosion resistance and dimensional stability without swelling. Noise and vibration damping are often a factor to reduce effects in the work place.

Applications

- Industrial machinary parts

- Fittings and fixtures

- Impellor for a water pump

- Flexible packaging

- Filters

General construction

The applications within the building industry can vary greatly. Offering performance alongside cost effectiveness, the benefits are balanced. Now there is growing demand for sustainable options to take into account the environmental impact. Resinex have many options for this growing market.

Applications

- Road bollards

- Buckets

- Building tools

- Dowels

- End caps

- Corrugated sheet

- Pipes

- Protective foam

General construction

The applications within the building industry can vary greatly. Offering performance alongside cost effectiveness, the benefits are balanced. Now there is growing demand for sustainable options to take into account the environmental impact. Resinex have many options for this growing market.

Applications

- Road bollards

- Buckets

- Building tools

- Dowels

- End caps

- Corrugated sheet

- Pipes

- Protective foam

Industrial machinery

Industrial machinary uses plastics in some of its working parts due to its cost effectiveness and durability. We are always trying to make machines quieter and by using plastic, we can improve noise and vibration.

Applications

- Bearings

- Gears

- Seals and gaskets

- Housings and enclosures

- Fluid handling applications

- Electrical insulation

- Conveyor components

Industrial machinery

Industrial machinary uses plastics in some of its working parts due to its cost effectiveness and durability. We are always trying to make machines quieter and by using plastic, we can improve noise and vibration.

Applications

- Bearings

- Gears

- Seals and gaskets

- Housings and enclosures

- Fluid handling applications

- Electrical insulation

- Conveyor components

Monofilaments

Single strands that can be used in various processes and applications.

Materials that are used to produce monofilaments:

PLA (Bio-sourced Polymer)

ABS

PET

Nylons

LLDPE

PP

Polymer is usually extruded to produce thin strands through carefully controlled conditions. The filament is cooled rapidly to maintain shape and size.

Applications

- Healthcare sector - sutures and testing procedures

- Netting and mesh

- Filament for 3D printing

- Bristles for brushes eg toothbrush

- Textiles - flexible fibres can be interwoven to produce elastic properties

- Bio based elastic monofilament

- Rope and twine

Monofilaments

Single strands that can be used in various processes and applications.

Materials that are used to produce monofilaments:

PLA (Bio-sourced Polymer)

ABS

PET

Nylons

LLDPE

PP

Polymer is usually extruded to produce thin strands through carefully controlled conditions. The filament is cooled rapidly to maintain shape and size.

Applications

- Healthcare sector - sutures and testing procedures

- Netting and mesh

- Filament for 3D printing

- Bristles for brushes eg toothbrush

- Textiles - flexible fibres can be interwoven to produce elastic properties

- Bio based elastic monofilament

- Rope and twine

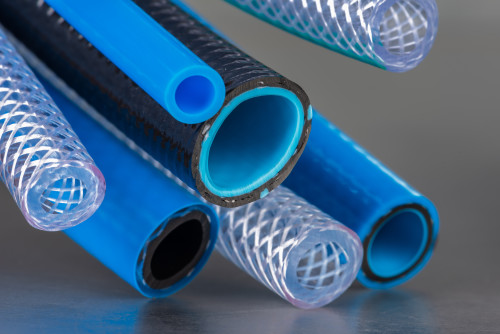

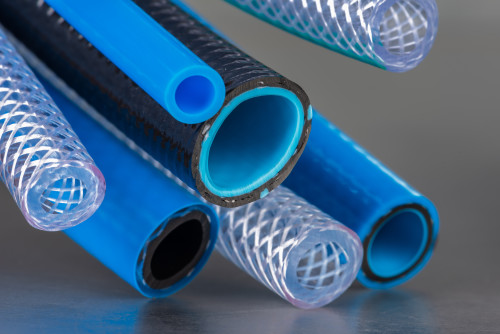

Pipes & Hoses

Pipes and hoses in the industrial sector follow the same premise as the consumer sector however, there may be more stringent requirements and certifications needed. Higher temperatures may be required for hoses and enhanced chemical resistance to suit the industrial environment.

This said, the materials of choice still remain with PP, PE and PVC, for chemical resistance and with PVC, some grades offering high temperature resistance. Polyurethane is a good material for abrasion resistance and used in water or compressed air hoses.

ABS is used in some pipes, fitting and valves as well as pipe flanges due to its impact resistance and electrical resistance.

Rubber is another material of choice due to its durability and high temperature resistance.

Applications

- Coupling and connectors

- Industrial hoses

- Hydraulic hoses

- Industrial piping

Pipes & Hoses

Pipes and hoses in the industrial sector follow the same premise as the consumer sector however, there may be more stringent requirements and certifications needed. Higher temperatures may be required for hoses and enhanced chemical resistance to suit the industrial environment.

This said, the materials of choice still remain with PP, PE and PVC, for chemical resistance and with PVC, some grades offering high temperature resistance. Polyurethane is a good material for abrasion resistance and used in water or compressed air hoses.

ABS is used in some pipes, fitting and valves as well as pipe flanges due to its impact resistance and electrical resistance.

Rubber is another material of choice due to its durability and high temperature resistance.

Applications

- Coupling and connectors

- Industrial hoses

- Hydraulic hoses

- Industrial piping

Power generation

Power generation is an important subject if we want to sustain our energy needs in the future. Developments are ongoing with manufacturing and with the domestic market. From the circular economy within the plastics manufacturing industry, ensuring recycling of plastic to provide a sustainable resource in plastics, to solar, wind and power.

Applications

- Solar panels

- Wind turbines

- Connectors

Power generation

Power generation is an important subject if we want to sustain our energy needs in the future. Developments are ongoing with manufacturing and with the domestic market. From the circular economy within the plastics manufacturing industry, ensuring recycling of plastic to provide a sustainable resource in plastics, to solar, wind and power.

Applications

- Solar panels

- Wind turbines

- Connectors

Ropes / ties / harness

There are many factors that will define what types of material is used:

excellent friction resistance

dimensional stability

mechanical strength

abrasion resistance

tension resistance

effective corrosion protection

Nylon is used in production of cable ties for its strength, heat resistance and creep resistance. PA12, Rilsamid, is used for its strength and as well as being resistance to moisture which is also a very good sustainable option with bio based grades. Rilsan PA11, is 100% renewable origin made from Castor oil.

A nylon block copolymer, Pebax, offers a degree of flexibility and low temperature resistance.

Applications

- Protective coatings for steel / wire ropes

- High performance ropes

- Cable ties

Ropes / ties / harness

There are many factors that will define what types of material is used:

excellent friction resistance

dimensional stability

mechanical strength

abrasion resistance

tension resistance

effective corrosion protection

Nylon is used in production of cable ties for its strength, heat resistance and creep resistance. PA12, Rilsamid, is used for its strength and as well as being resistance to moisture which is also a very good sustainable option with bio based grades. Rilsan PA11, is 100% renewable origin made from Castor oil.

A nylon block copolymer, Pebax, offers a degree of flexibility and low temperature resistance.

Applications

- Protective coatings for steel / wire ropes

- High performance ropes

- Cable ties

Sanitation

Our need to minimise the spread of bacteria and viruses is never more important in our day to day lives. This can be via hand cleaning and washing facilities to waste management.

From PP and PVC for pipes and connectors to ABS for housings of towel dispensers and soap dispensers.

We have materials that will pass the necessary certifications of water approvals WRAS, KTW or NSF.

Often there is a need for higher chemical resistance due to the nature of eliminiating bacteria via chlorine. We have many options of engineering materials with chlorine resistance (POM) and also high perfomance materials (such as PVDF) with excellent chemical resistance to combat these harsh conditions.

There are also possibilities of using masterbatch additives, such as antimicrobial, to enhance the properties of the material to suit the conditions required, for instance in food safety.

Applications

- Bathroom parts

- Pipes and connectors

- Towel dispensers

- Soap dispensers

- Flush plates

Sanitation

Our need to minimise the spread of bacteria and viruses is never more important in our day to day lives. This can be via hand cleaning and washing facilities to waste management.

From PP and PVC for pipes and connectors to ABS for housings of towel dispensers and soap dispensers.

We have materials that will pass the necessary certifications of water approvals WRAS, KTW or NSF.

Often there is a need for higher chemical resistance due to the nature of eliminiating bacteria via chlorine. We have many options of engineering materials with chlorine resistance (POM) and also high perfomance materials (such as PVDF) with excellent chemical resistance to combat these harsh conditions.

There are also possibilities of using masterbatch additives, such as antimicrobial, to enhance the properties of the material to suit the conditions required, for instance in food safety.

Applications

- Bathroom parts

- Pipes and connectors

- Towel dispensers

- Soap dispensers

- Flush plates

Seals & gaskets

Seals and gaskets are used to create a barrier between 2 parts to avoid leaking. They're used commonly in many industries and are very important to reduce noise and vibration. Usually made from EPDM rubber, Thermoplastic Elastomers (TPEs and TPVs) depending on the requirements and conditons of the parts.

Seals can be found in:

engine parts

pumps

rotating shafts

Gaskets are usually designed to seal two non-moving parts but typically need to withstand:

abrasion

vibration

impact

high temperatures

chemicals

Applications

- Industrial machinary

- Automotive under bonnet

- Sanitation pipes

- Food industry

Seals & gaskets

Seals and gaskets are used to create a barrier between 2 parts to avoid leaking. They're used commonly in many industries and are very important to reduce noise and vibration. Usually made from EPDM rubber, Thermoplastic Elastomers (TPEs and TPVs) depending on the requirements and conditons of the parts.

Seals can be found in:

engine parts

pumps

rotating shafts

Gaskets are usually designed to seal two non-moving parts but typically need to withstand:

abrasion

vibration

impact

high temperatures

chemicals

Applications

- Industrial machinary

- Automotive under bonnet

- Sanitation pipes

- Food industry

Sheets / shapes

Plastic sheets, produced through the extrusion process, have diverse uses. They can be thermoformed to create trays, containers, and protective covers. Additionally, these sheets allow for creative freedom by combining different materials and incorporating various designs. For machining small volumes of parts or creating rods for display, plastic sheets offer flexibility. Custom-specific requirements can be met using any suitable material.

Applications

- Roofing

- Display

- Packaging

- Rod for display items or welding

- Stock shapes

- Machined parts

Sheets / shapes

Plastic sheets, produced through the extrusion process, have diverse uses. They can be thermoformed to create trays, containers, and protective covers. Additionally, these sheets allow for creative freedom by combining different materials and incorporating various designs. For machining small volumes of parts or creating rods for display, plastic sheets offer flexibility. Custom-specific requirements can be met using any suitable material.

Applications

- Roofing

- Display

- Packaging

- Rod for display items or welding

- Stock shapes

- Machined parts