Process and Applications:

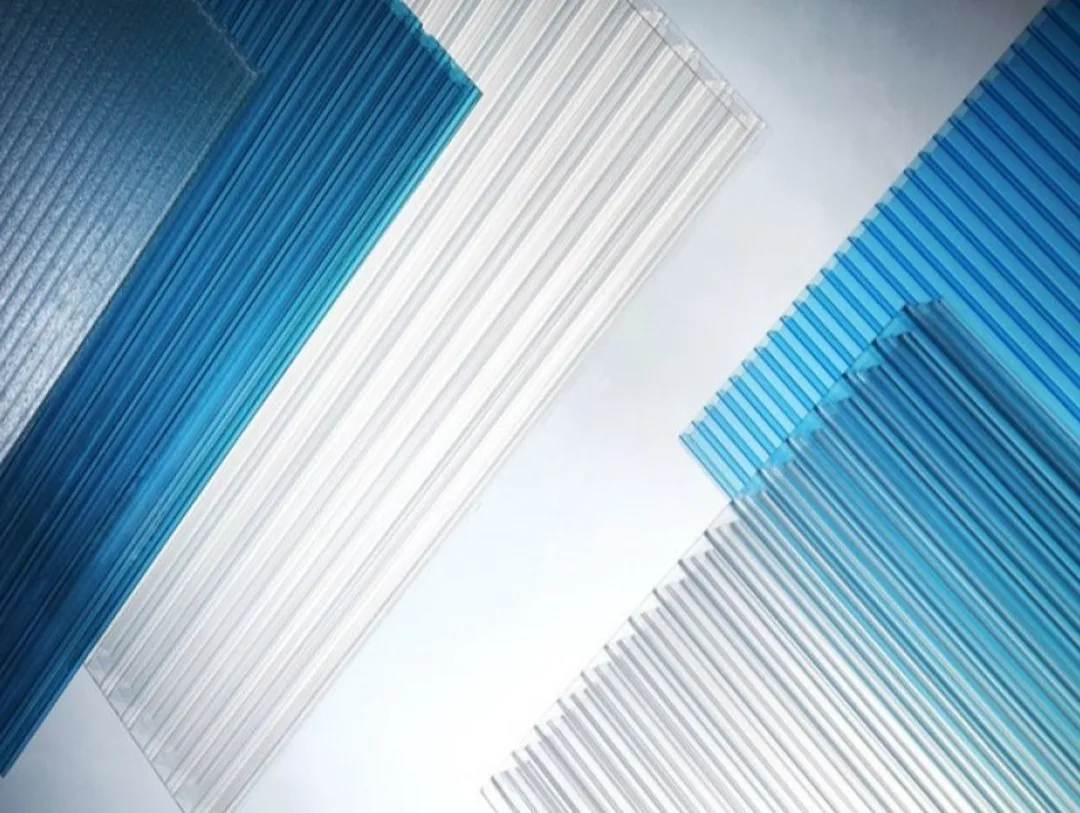

Versatile Resin Use: Different resins are processed to create a wide range of plastic sheet thicknesses.

Thermoforming: Thinner gauge sheets are thermoformed into consumer packaging like drink cups, deli containers, and baby wipe containers.

Industrial Uses: Thicker sheets have robust applications, including truck bed liners, pallets, and heavy-duty equipment.

Environmental Applications: Geomembranes derived from sheet extrusion are crucial in large-scale environmental projects, such as mining and waste management systems.

Extrusion Process Details:

Cooling Mechanism: The process involves cooling the extruded plastic through a series of calender or "chill" rolls, often three or four in number.

Texture and Thickness: These rolls not only cool the sheet but also define its thickness and surface texture (e.g., levant, smooth, haircell).

Advanced Manufacturing Techniques:

Co-Extrusion: This specialized technique applies multiple layers to the base sheet, enhancing properties like tactile "grip," UV resistance, matte aesthetics, or reflective qualities.

By utilising advanced sheet extrusion techniques, manufacturers can produce a diverse array of products tailored to specific uses, from everyday consumer goods to specialized industrial components.