To meet the requirements of this growing market, Resinex has a dedicated and experienced E&E and technical team to assist you with the next generation of electronic products.

This includes close cooperation during every step of your product development from material selection and Moldflow® simulations.

With our supply partners, Celanese, Trinseo, Lotte and Envalior, we have an extensive range to supply with your needs in mind as well as looking at our Ravago range of solutions.

CHARACTERISTICS:

Cost-competitive

Chlorine and bromine free

Excellent electrical properties

Best-in-class dimensional stability

Transparent and opaque

Resinex polymer portfolio meets the most stringent international and local environmental, electrical ,electronics, household and UL standards:

RoHS (restriction on the use of certain hazardous substances)

Directive 2002/95/EU WEEE (Waste from Electrical and Electronic Equipment)

Directive 2002/96/EU VDE 0472 part 815

EN 60695 or UL 94 for flammability

ISO 4892-2 or UL 746C for weathering

EN 60998 connecting devices for low voltage circuits

EN 62053 electricity meters

Related Products

Market Segments

Consumer Electronics

Electricity powers almost every aspect of our lives, at home and in our jobs, at work and at play. And everywhere that we find electricity, we also find plastics. In the kitchen, there are the labour-saving devices that we wouldn’t be without; microwave ovens, kettles, coffee machines, air fryers.

In the living room is the television and our smartphones are becoming an important part of every day living.

Plastics make progress possible, making electrical goods safer, lighter, more attractive, quieter. more environmentally friendly and more durable.

Electrical applications use plastic:

to act as an insulator

to have high distortion resistance

to have ignition-resistance

demostrating glow wire temperature resistance in order to meet various global and local standards.

Currently the industry is looking at the environmental impact and eco friendly materials.

Applications

- Connecting devices

- Enclosures for household insulations

- Switchgear

- Electricity meter housings

- Electronic housings

Consumer Electronics

Electricity powers almost every aspect of our lives, at home and in our jobs, at work and at play. And everywhere that we find electricity, we also find plastics. In the kitchen, there are the labour-saving devices that we wouldn’t be without; microwave ovens, kettles, coffee machines, air fryers.

In the living room is the television and our smartphones are becoming an important part of every day living.

Plastics make progress possible, making electrical goods safer, lighter, more attractive, quieter. more environmentally friendly and more durable.

Electrical applications use plastic:

to act as an insulator

to have high distortion resistance

to have ignition-resistance

demostrating glow wire temperature resistance in order to meet various global and local standards.

Currently the industry is looking at the environmental impact and eco friendly materials.

Applications

- Connecting devices

- Enclosures for household insulations

- Switchgear

- Electricity meter housings

- Electronic housings

Electrical

Electrical applications that have electrical wires embedded in the plastic cover require the plastic to act as an insulator. This requires resins with high distortion resistance, ignition-resistance, and glow wire temperature resistance in order to meet various global and local standards.

Our broad portfolio provides ignition-resistant, completely halogen-free solutions for many electrical applications, including switches, plugs and meters.

Electric vehicles are changing automotive engineering that means new thermoplastics requirements. Resinex provides solutions for electronic and electrical vehicles applications, including 5G connectivity, EV charger and wallboxes.

Applications

- Laptops

- Mobile

- 5G communication

- TV

Electrical

Electrical applications that have electrical wires embedded in the plastic cover require the plastic to act as an insulator. This requires resins with high distortion resistance, ignition-resistance, and glow wire temperature resistance in order to meet various global and local standards.

Our broad portfolio provides ignition-resistant, completely halogen-free solutions for many electrical applications, including switches, plugs and meters.

Electric vehicles are changing automotive engineering that means new thermoplastics requirements. Resinex provides solutions for electronic and electrical vehicles applications, including 5G connectivity, EV charger and wallboxes.

Applications

- Laptops

- Mobile

- 5G communication

- TV

Lighting

As end users are making the transition to non-incandescent lighting, such as compact fluorescent lights (CFLs) and the quickly emerging LED (solid-state) lighting, high-light transmission, opalescence and durability are key requirements. Our polycarbonate resins, PC compounds, SAN resins and ASA and acrylic provide these features and more. Resinex´s offerings for electrical & lighting applications contain flame retardant technology that is chlorine, bromine, fluorine and phosphorous free while providing the same flame retardant performance the industry is used to.

LIGHTING Performance:

Thermal stability

Optical clarity

Impact resistance

Dimensional stability

Heat stability

Weather resistance

Light management control

Proprietary opalescence technology

Applications

- Diffusers and lenses

- Housings

- Emergency lights

- Explosion proof lights

- Reflectors

- Fixtures and fittings

Lighting

As end users are making the transition to non-incandescent lighting, such as compact fluorescent lights (CFLs) and the quickly emerging LED (solid-state) lighting, high-light transmission, opalescence and durability are key requirements. Our polycarbonate resins, PC compounds, SAN resins and ASA and acrylic provide these features and more. Resinex´s offerings for electrical & lighting applications contain flame retardant technology that is chlorine, bromine, fluorine and phosphorous free while providing the same flame retardant performance the industry is used to.

LIGHTING Performance:

Thermal stability

Optical clarity

Impact resistance

Dimensional stability

Heat stability

Weather resistance

Light management control

Proprietary opalescence technology

Applications

- Diffusers and lenses

- Housings

- Emergency lights

- Explosion proof lights

- Reflectors

- Fixtures and fittings

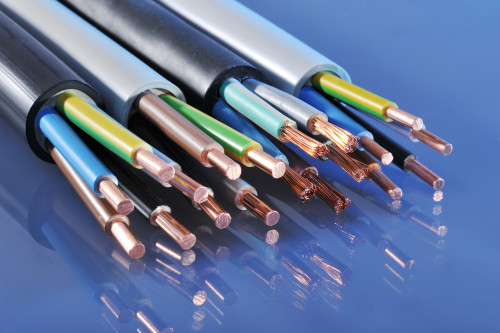

Wire and Cable

Plastics in the wire and cable industry are used in diverse applications. With properties ranging from:

Flame retardant

Heat resistance

Electrically conductive

Electrically insulating

Good flexibility

Cross linking capabilities

These are just a few of the requirements in the industry where Resinex can offer a wide range of materials to suit your needs.

Applications

- Jacketing

- Insulation

- Heat shrink tubing

- Sheathing

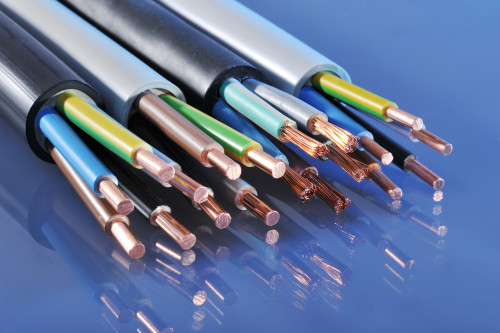

Wire and Cable

Plastics in the wire and cable industry are used in diverse applications. With properties ranging from:

Flame retardant

Heat resistance

Electrically conductive

Electrically insulating

Good flexibility

Cross linking capabilities

These are just a few of the requirements in the industry where Resinex can offer a wide range of materials to suit your needs.

Applications

- Jacketing

- Insulation

- Heat shrink tubing

- Sheathing

Electrical components

Electrical components are usually classed as the fundamemental building blocks of electrical circuits with the primary function to control or manage electricity. The parts are often small, requiring high flow materials with flame retardency. The ability to pass glow wire regulations is often a requirement. In addition, parts are soldered to circuit boards, requirement SMT functionality.

Applications

- Connectors

- Circuit breakers

- Connector housings

- Busbars

- PCB board connectors

- Optical fibre housing

- Transistors

- Capacitors

Electrical components

Electrical components are usually classed as the fundamemental building blocks of electrical circuits with the primary function to control or manage electricity. The parts are often small, requiring high flow materials with flame retardency. The ability to pass glow wire regulations is often a requirement. In addition, parts are soldered to circuit boards, requirement SMT functionality.

Applications

- Connectors

- Circuit breakers

- Connector housings

- Busbars

- PCB board connectors

- Optical fibre housing

- Transistors

- Capacitors